Hyundai Santa Fe: ESP(Electronic Stability Program) System / Description and operation

Hyundai Santa Fe (TM) 2019-2025 Service Manual / Brake System / ESP(Electronic Stability Program) System / Description and operation

| Description of ESP |

ESP recognizes critical driving conditions, such as panic reactions in dangerous

situations, and stabilizes the vehicle by wheel-individual braking and engine

control intervention.

ESP adds a further function known as Active Yaw Control (AYC) to the ABS, TCS,

EBD and ESP functions. Whereas the ABS/TCS function controls wheel slip during

braking and acceleration and, thus, mainly intervenes in the longitudinal dynamics

of the vehicle, active yaw control stabilizes the vehicle about its vertical

axis.

This is achieved by wheel individual brake intervention and adaptation of the

momentary engine torque with no need for any action to be taken by the driver.

ESP essentially consists of three assemblies : the sensors, the electronic control

unit and the actuators.

The stability control feature works under all driving and operating conditions.

Under certain driving conditions, the ABS/TCS function can be activated simultaneously

with the ESP function in response to a command by the driver.

In the event of a failure of the stability control function, the basic safety

function, ABS, is still maintained.

Description of ESP Control

ESP system includes ABS/EBD, TCS and AYC function.

ABS/EBD function : The ECU changes the active sensor signal (current shift)

coming from the four wheel sensors to the square wave. By using the input of

above signals, the ECU calculates the vehicle speed and the acceleration & deceleration

of the four wheels. And, the ECU judges whether the ABS/EBD should be actuated

or not.

TCS function prevents the wheel slip of drive direction by adding the brake

pressure and engine torque reduction via CAN communication. TCS function uses

the wheel speed sensor signal to determine the wheel slip as far as ABS function.

AYC function prevents unstable maneuver of the vehicle. To determine the vehicle

maneuver, AYC function uses the maneuver sensor signals(Yaw Rate Sensor, Lateral

Acceleration Sensor, Steering Wheel Angle Sensor).

If vehicle maneuver is unstable (Over Steer or Under Steer), AYC function applies

the brake pressure on certain wheel, and send engine torque reduction signal

by CAN.

After the key-on, the ECU continually diagnoses the system failure. (self-diagnosis)If

the system failure is detected, the ECU informs driver of the system failure

through the BRAKE/ABS/ESP warning lamp. (fail-safe warning)

Input and Output Diagram

| ESP Operation Mode |

| 1. |

STEP 1

The ESP analyzes the intention of the driver.

|

| 2. |

STEP 2

It analyzes the movement of the ESP vehicle.

|

| 3. |

STEP 3

The HECU calculates the required strategy, then actuates the appropriate

valves and sents torque control requests via CAN to maintain vehicle

stability.

|

| ESP Hydraulic System Diagram |

| 1. |

ESP Non-operation : Normal braking.

|

| 2. |

ESP operation

Warning Lamp Control

|

||||||||||||||||||||||

ABS Warning Lamp module

The active ABS warning lamp module indicates the self-test and failure status

of the ABS. The ABS warning lamp shall be on :

| – |

During the initialization phase after IGN ON. (continuously 3 seconds).

|

| – |

In the event of inhibition of ABS functions by failure.

|

| – |

During diagnostic mode.

|

| – |

When the ECU Connector is seperated from ECU.

|

| – |

Cluster lamp is ON when communication is impossible with CAN module.

|

EBD/Parking Brake Warning Lamp Module

The active EBD warning lamp module indicates the self-test and failure status

of the EBD. However, in case the Parking Brake Switch is turned on, the EBD

warning lamp is always turned on regardless of EBD functions. The EBD warning

lamp shallbe on :

| – |

During the initialization phase after IGN ON. (continuously 3 seconds).

|

| – |

When the Parking Brake Switch is ON or brake fluid level is low.

|

| – |

When the EBD function is out of order .

|

| – |

During diagnostic mode.

|

| – |

When the ECU Connector is seperated from ECU.

|

| – |

Cluster lamp is ON when communication is impossible with CAN module.

|

ESP Function / Warning Lamp (ESP System)

The ESP function/warning lamp indicates the self-test and failure status of

the ESP.

The ESP function/warning lamp is turned on under the following conditions :

| – |

During the initialization phase after IGN ON. (continuously 3 seconds).

|

| – |

When the ESP function is inhibited by system failure.

|

| – |

When the ESP control is operating. (Blinking - 2Hz)

|

| – |

During diagnostic mode.(Except standard mode)

|

| – |

Cluster lamp is ON when communication is impossible with CAN module.

|

ESP OFF Lamp (ESP System)

The ESP Off lamp indicates the self-test and operating status of the ESP.

The ESP Off lamp operates under the following conditions :

| – |

During the initialization mode after IGN ON. (continuously 3 seconds).

|

| – |

ESP Off lamp is On when driver input the ESP Off switch.

|

ESP ON / OFF Switch (ESP System)

The ESP On/Off Switch shall be used to toggle the ESP function between On/Off

states based upon driver input.

The On/Off switch shall be a normally open, momentary contact switch.Closed

contacts switch the circuit to ignition.

Initial status of the ESP function is on and switch toggle the state.

Components and components location

Components and components location

Components

1. ABS control

module (HECU)

2. Front wheel speed sensor

3. Rear wheel speed sensor

4. ABS warning

lamp

5...

Schematic diagrams

Schematic diagrams

Circuit Diagram

ABS / ESC

ESCi/ESCi+(EPB Integrated)

Terminal Function

ABS / ESC

PIN No

Desciption

Current

Resistance

1

Pump motor supply voltage

60 A

10 mΩ

2

-

-

-

3

-

-

-

4

C-CAN High

100 mA

250 mΩ

5

C-CAN Low

100 mA

250 mΩ

6

-

-

-

7

P-CAN Low

100 mA

250 MΩ

8

P-CAN High

100 mA

250 MΩ

9

Wheel speed sensor supply voltage (Left rear)

100 mA

250 MΩ

10

Wheel speed sensor supply voltage (Right rear)

100 mA

250 MΩ

11

Wheel speed sensor supply voltage (Right front)

100 mA

250 MΩ

12

Wheel speed sensor supply voltage (Left front)

100 mA

250 MΩ

13

Recycle pump ground

40 A

10 MΩ

14

-

-

-

15

Clutch stroke sensor signal

1...

Categories

- Manuals Home

- 4th Generation Santa Fe Owners Manual

- 4th Generation Santa Fe Service Manual

- Resetting the power liftgate

- Instrument cluster

- Warning and indicator lights

- New on site

- Most important about car

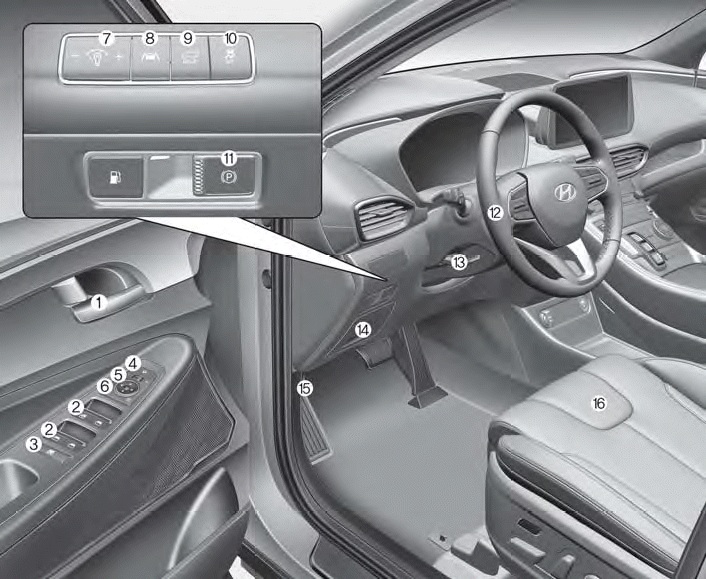

Interior Overview

1. Inside door handle

2. Power window switches

3. Power window lock button/Electronic child safety lock button

4. Side view mirror folding button

5. Side view mirror control switch

6. Central door lock switch

7. Instrument panel illumination control switch

Copyright © 2025 www.hsafe4.com