Hyundai Santa Fe: Lubrication System / Oil Pan. Repair procedures

Hyundai Santa Fe (TM) 2019-2025 Service Manual / Engine Mechanical System / Lubrication System / Oil Pan. Repair procedures

| Removal |

|

| 1. |

Disconnect the battery negative "-" terminal.

|

| 2. |

Remove the drive belt.

(Refer to Timing System - "Drive Belt")

|

| 3. |

Disconnect the compressor ECV connector, and then by loosening the mounting

bolts, widen the gap between the compressor from the engine to remove

the A/C compressor bracket.

(Refer to Air Conditioning System - "Compressor")

|

| 4. |

Remove the A/C compressor bracket (A).

|

| 5. |

Remove the dust cover (A).

|

| 6. |

Remove the oil pan (A). Insert the blade of SST (09215-3C000) between

the ladder frame and oil pan. Cut off applied sealer and remove the

lower oil pan.

|

| Installation |

| 1. |

Install the oil pan.

|

| 2. |

Install the A/C compressor bracket (A).

|

| 3. |

Install the A/C compressor mounting bolts.

(Refer to Heateng, Ventilation, Air conditioning - "Compressor")

|

| 4. |

Refill engine with engine oil.

|

Oil Pump. Repair procedures

Oil Pump. Repair procedures

Removal

•

Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and canister) when

raising the vehicle using the lift...

Oil Pressure Switch. Repair procedures

Oil Pressure Switch. Repair procedures

Removal and Installation

•

Be careful not to damage the parts located under the vehicle

(floor under cover, fuel filter, fuel tank and canister) when

raising the vehicle using the lift...

Other information:

Hyundai Santa Fe (TM) 2019-2025 Owner's Manual: Air bag - supplemental restraint system

1. Driver’s front air bag 2. Passenger’s front air bag 3. Side air bag 4. Curtain air bag The vehicles are equipped with a Supplemental Air Bag System for the driver’s seat and front passenger’s seats. The front air bags are designed to supplement the three-point seat belts...

Hyundai Santa Fe (TM) 2019-2025 Service Manual: General information

General Troubleshooting Information Before Troubleshooting 1. Check applicable fuses in the appropriate fuse/relay box. 2. Using the battery checker (MCR-570 KIT), check the battery for damage, state of charge, and clean and tight connections...

Categories

- Manuals Home

- 4th Generation Santa Fe Owners Manual

- 4th Generation Santa Fe Service Manual

- Folding the side view mirror

- Electronic Parking Brake (EPB) warning light. AUTO HOLD indicator light

- Electronic child safety lock

- New on site

- Most important about car

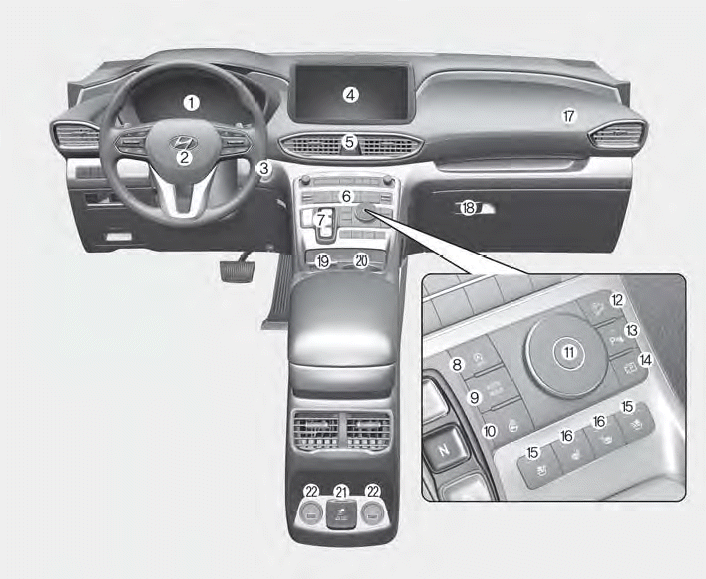

Instrument panel overview

1. Instrument cluster

2. Driver’s front air bag

3. Engine Start/Stop button

4. Infotainment system

5. Hazard warning lamp switch

6. Climate control system

7. Shift button

8. ISG (Idle Stop and Go) button

9. Auto Hold button

10. Heated steering wheel button

11. Drive mode button

12. DBC (Downhill Brake Control) button

13. Parking Safety button

14. Parking/View button

15. Air ventilation seat button

16. Seat warmer

17. Passenger’s front air bag

18. Glove box

19. Wireless charging system pad

20. Cup holder

21. AC inverter

22. USB charger

Copyright © 2025 www.hsafe4.com